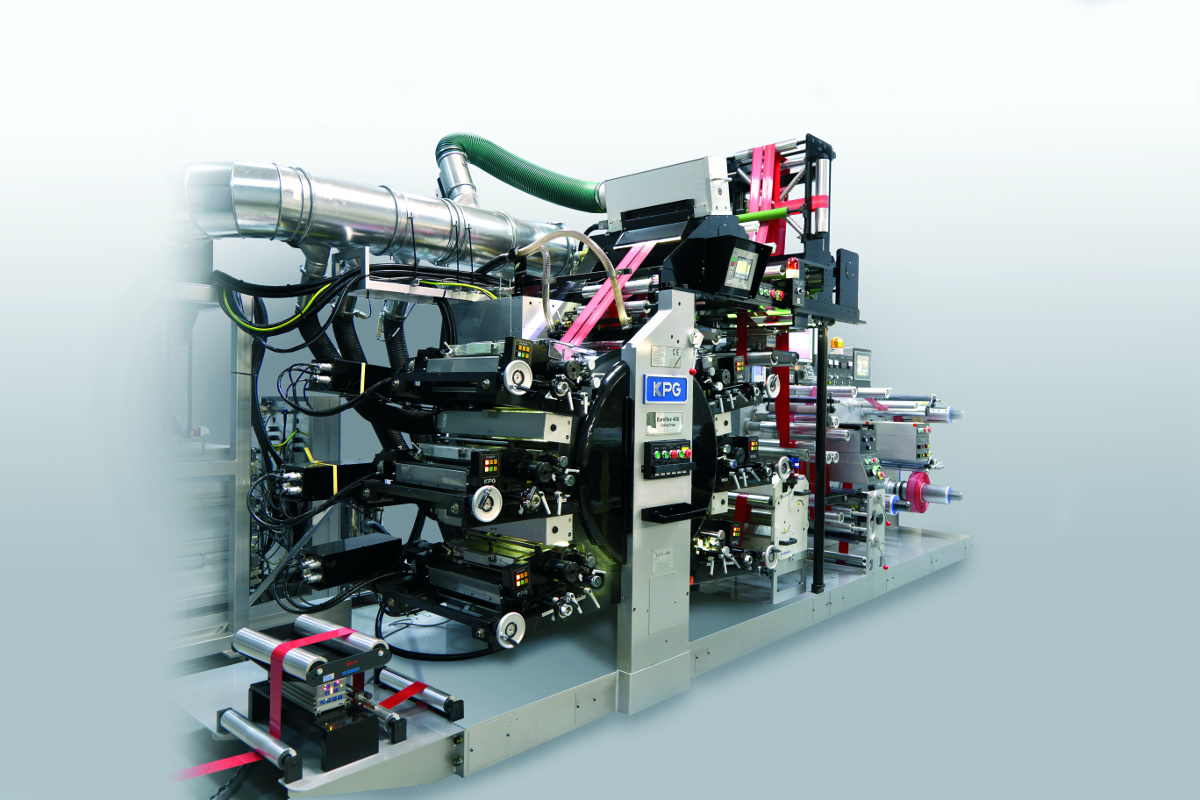

Today Biostar, having a wide range of up-to-date printing presses can offer its customers high-quality two-component and UV-printing.

Printing with two-component inks — a type of letterpress printing using flexible photopolymer printing plates (cliché) with low viscosity rapid-setting inks.

The high level of applied technology guarantees excellent image quality and high-class color reproduction of pattern of any complexity.

UV printing — the printing with ultra-violet inks that are immediately cured due to reaction of photopolymerization carried out exposed to a strong ultraviolet radiation.

Advantages of ultra-violet printing:

Applied inks, regardless of the type of printing, have a high degree of grease and water resistance. Print applied to the casing does not deteriorate under the influence of a temperature, react to smoke fume components or get modified during the heat treatment; it is abrasion and stretch resistant and shrinks along with the casing. An important advantage of applied inks is full guarantee of safety for the consumers’ health.

Experienced personnel and client-centered approach are the key features that allow us to provide printing services at the highest professional level.